Quick Listen:

Picture a world where your favorite pair of underwear doesn't just feel good but does good crafted from silky, breathable fabric that's kind to the planet. That's no longer a distant dream. Across the globe, eco-conscious consumers are pushing the textile industry to rethink how clothes, especially intimate apparel, are made. From beechwood-derived micromodal to groundbreaking recycling projects, the innerwear sector is weaving sustainability into its very fabric.

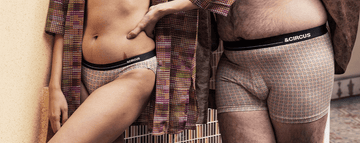

Uncomfortable underwear shouldn't steal your confidence. At Andcircus, we craft ultra-soft, sustainable Lenzing Modal Micro® innerwear for every body, XS to 5XL. From briefs to bras, our custom packs fit you perfectly. Shop risk-free with our 100% satisfaction guarantee and embrace comfort that includes everyone. #LoveEveryBody. Shop Now!

Eco-Conscious Consumers Fuel Breakthroughs in Sustainable Textiles

The fashion industry, long criticized for its environmental toll, is undergoing a quiet revolution. Spurred by growing awareness of climate change and resource depletion, consumers are demanding more than just style and comfort they want clothes that align with their values. The innerwear market, in particular, is at the forefront of this shift. Brands are turning to innovative materials like micromodal, a buttery-soft fiber made from sustainably sourced beechwood, which uses significantly less water than conventional cotton. According to environmental sustainable innovation principles, these efforts integrate eco-conscious practices into every stage of production, from sourcing to manufacturing, aligning with circular economy models that prioritize restorative systems.

But it's not just about new fabrics. The industry is embracing closed-loop manufacturing, where waste is minimized, and materials are reused or recycled. Take Project Re:claim in Kettering, Northamptonshire, a pioneering initiative that's rewriting the rules of textile recycling. By melting down discarded polyester football shirts, banners, and uniforms, this joint venture between the Salvation Army and Project Plan B transforms waste into granules that can be spun into new yarn. In 2023 alone, they recycled 2,500 tonnes of textiles, with plans to double that in 2025. Retail giants like Tesco and John Lewis are jumping on board, signaling a broader industry shift toward circularity.

Innovations Reshaping the Innerwear Landscape

The push for sustainability is sparking a wave of creativity in textile development. Micromodal, for instance, isn't just soft and breathable it's a game-changer for eco-friendly innerwear. Sourced from beechwood, it requires less water and energy than traditional cotton, making it a darling of brands crafting everything from gender-neutral briefs to maternity-safe lingerie. Meanwhile, closed-loop systems are slashing waste by reusing water and chemicals in production, a practice gaining traction in ethical mills across Asia and Europe.

Then there's the rise of biodegradable dyes and waterless dyeing technologies, which drastically cut the environmental footprint of textile coloring. These innovations tackle one of fashion's dirtiest secrets: the massive water pollution caused by traditional dyeing processes. Add to that the growing popularity of take-back programs, where brands encourage consumers to return worn garments for recycling, and you've got a glimpse of a future where fashion doesn't cost the Earth. BCC Research projects that the global sustainable fabrics market will see robust growth through 2029, driven by consumer demand and technological advancements.

Brands Leading the Charge

Some innerwear brands are already walking the talk. Picture a small, ethical brand producing biodegradable lingerie that's safe for maternity wear and certified by OEKO-TEX® or the Forest Stewardship Council (FSC). These certifications ensure that every step, from fiber sourcing to final stitching, meets strict environmental and ethical standards. In Europe, collaborations between designers and textile innovators are yielding gender-inclusive collections that prioritize both comfort and sustainability. Meanwhile, in Asia, mills are partnering with brands to scale up micromodal production, ensuring that eco-friendly options aren't just niche but mainstream.

Project Re:claim's work with retailers like David Luke, a school uniform manufacturer, shows how even specialized sectors are embracing recycled polyester. By using infrared sensors to sort textiles and redirect polyester to pellet-making machines, they're closing the loop on waste. These efforts aren't just good PR they're building consumer trust in an industry often plagued by skepticism.

The Roadblocks to Going Green

Yet, for all the progress, scaling sustainable textiles isn't easy. Micromodal, while eco-friendly, remains pricier than conventional cotton or synthetics, putting it out of reach for some brands and consumers. Limited supplier infrastructure further complicates things there simply aren't enough mills equipped to produce sustainable fabrics at scale. Greenwashing is another hurdle. With some brands exaggerating their eco-credentials, consumers are growing wary, demanding transparency and standardized certifications to separate genuine efforts from marketing ploys.

Then there's the challenge of balancing performance with sustainability. Innerwear, especially for maternity or activewear, needs to be stretchy, durable, and comfortable. Finding eco-friendly materials that tick all those boxes without compromising on quality is no small feat. As Data Bridge Market Research notes, the global textile market, valued at $1,122 million in 2022, is expected to soar to $2,961.72 million by 2030, with a CAGR of 12.90%. But sustainable options must compete with cheaper, less eco-friendly alternatives in a crowded market.

Opportunities for a Greener Future

Despite these challenges, the opportunities are immense. Eco-conscious brands are finding that authenticity pays off. Transparent supply chains often tracked via blockchain or digital labeling build consumer loyalty and justify premium pricing. Compliance with environmental, social, and governance (ESG) standards is also becoming a competitive edge, helping brands meet tightening regulations and corporate sustainability goals. Niche markets, like maternity and gender-inclusive innerwear, are proving particularly fertile ground for growth, as consumers seek products tailored to their needs and values.

The numbers back this up. The global textile market's projected growth reflects rising demand across sectors like healthcare, defense, and automotive, but it's the innerwear segment's focus on sustainability that's capturing hearts and wallets. Brands that invest in traceable, eco-friendly products aren't just doing good they're carving out a distinct market position in an increasingly crowded field.

A Memorable The Fabric of Tomorrow

As we stand at the crossroads of fashion and sustainability, the innerwear industry is showing us what's possible. From micromodal briefs to recycled polyester bras, the fabrics we wear closest to our skin are becoming a testament to innovation and responsibility. Experts predict that the next decade will bring even more breakthroughs think bio-based elastics or algae-derived fibers that push the boundaries of what sustainable textiles can do. But for these innovations to scale, brands, suppliers, and researchers must work together to standardize eco-certifications and rebuild consumer trust.

In a world where every purchase is a statement, sustainable innerwear is more than a trend it's a movement. It's about choosing comfort that doesn't come at the planet's expense. It's about wearing your values, quite literally, next to your skin. As initiatives like Project Re:claim and the rise of micromodal prove, the future of fashion isn't just green it's personal, purposeful, and poised to redefine how we dress for the world we want.

Frequently Asked Questions

How is environmental awareness influencing textile innovation in the innerwear industry?

Growing consumer demand for eco-friendly clothing is driving major innovations in the innerwear sector. Brands are embracing sustainable materials like micromodal made from beechwood and adopting closed-loop manufacturing processes that reduce waste and conserve resources.

What are some key sustainable materials being used in modern innerwear?

Materials like micromodal, derived from sustainably sourced beechwood, are gaining popularity due to their softness and low environmental impact. Other innovations include recycled polyester from old garments and biodegradable dyes that drastically reduce water pollution in the dyeing process.

What challenges do sustainable innerwear brands face today?

Key hurdles include the higher cost of eco-friendly fabrics, limited large-scale supplier infrastructure, and consumer skepticism due to greenwashing. To address this, brands are focusing on transparency, certifications like OEKO-TEX® and FSC, and traceable supply chains to build trust and justify premium pricing.

Disclaimer: The above helpful resources content contains personal opinions and experiences. The information provided is for general knowledge and does not constitute professional advice.

You may also be interested in: Why Eco-Friendly Bras and Panties Are the New Standard in Intimates

Uncomfortable underwear shouldn't steal your confidence. At Andcircus, we craft ultra-soft, sustainable Lenzing Modal Micro® innerwear for every body, XS to 5XL. From briefs to bras, our custom packs fit you perfectly. Shop risk-free with our 100% satisfaction guarantee and embrace comfort that includes everyone. #LoveEveryBody. Shop Now!