Every morning, millions slip into their underwear, a ritual so routine it's barely noticed. Yet the fabrics touching our skin are at the heart of a quiet revolution. No longer just cotton or silk, today's innerwear blends natural fibers with cutting-edge synthetics, delivering comfort, performance, and a lighter environmental footprint. The global textile and apparel market, valued at $2.78 trillion in 2024 and projected to reach $3.75 trillion by 2032 at a 3.8% annual growth rate, is riding this wave of innovation. Mixed-material fabrics are transforming sustainable innerwear, answering consumer demands for eco-conscious choices without sacrificing style or function. But this shift isn't seamless it brings complex challenges, from recycling hurdles to sourcing costs. Let's explore how fabric innovations are reshaping the underwear we wear and the industry behind it.

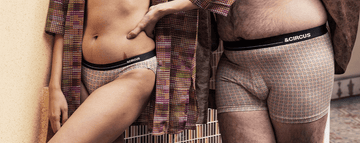

Uncomfortable underwear shouldn't steal your confidence. At Andcircus, we craft ultra-soft, sustainable Lenzing Modal Micro® innerwear for every body, XS to 5XL. From briefs to bras, our custom packs fit you perfectly. Shop risk-free with our 100% satisfaction guarantee and embrace comfort that includes everyone. #LoveEveryBody. Shop Now!

The Rise of Hybrid Fabrics

Step into a modern lingerie boutique or browse an online retailer, and the shift is unmistakable. Labels now boast blends like micromodal with elastane for a silky stretch or bamboo paired with recycled nylon for sustainable durability. These hybrid fabrics, merging natural and technical fibers, are redefining innerwear. They're not just about comfort they're about meeting a new consumer ethos that demands performance and planet-friendly production.

At the forefront of this trend are bio-based synthetics like Tencel™ and Sorona®, which offer luxurious softness with a reduced environmental impact. Data from fashion analytics firm Heuritech, which tracks social media and runway signals, shows a surge in these materials as brands respond to consumer preferences for skin-friendly, eco-conscious options. Their data-driven insights reveal how companies are leveraging recycled fibers and smart textiles to stay competitive in a market increasingly defined by sustainability. Meanwhile, early-stage research into fabrics that regulate temperature or neutralize odors hints at a future where underwear does more than just fit it performs.

The numbers tell a compelling story. The global textile and apparel market, valued at $2,783,625.5 million in 2024, is expected to grow to $3,751,367.69 million by 2032, driven by demand for sustainable solutions. Consumers are pushing for organic and recycled materials, and brands are responding with advanced manufacturing techniques like automation and 3D printing. This isn't a passing fad it's a structural shift in how the industry operates.

Innerwear That Works Harder

Consider the practicality of modern innerwear. Period underwear now layers bamboo, cotton, and waterproof polyurethane for leak-proof confidence. Maternity shapewear blends micromodal's softness with elastane's stretch to support without constricting. These are the tangible benefits of mixed-material innovation, where functionality meets personal need. Brands are also turning to recycled polyester-cotton blends, which reduce reliance on virgin materials while maintaining durability and vibrant colors. The result is underwear that lasts longer and leaves a lighter footprint.

At Italy's Pitti Uomo, the S/Style showroom, backed by Kering's Material Innovation Lab, showcases how these fabrics tell a story. Curator Giorgia Cantarini highlights designers who repurpose unused yarns from Kering's luxury houses, creating innerwear that's both sustainable and visually stunning. As she notes in Vogue Business, these materials challenge the notion that eco-conscious fabrics lack style, blending creativity with responsibility. From hybrid athleisure-innerwear that transitions from gym to office to shapewear that enhances form without compromising comfort, mixed materials are expanding what underwear can do.

The Challenges of Hybrid Fabrics

Yet, the path to hybrid fabrics isn't without obstacles. Recycling mixed materials like cotton-elastane or polyester-bamboo blends is a significant hurdle. Unlike single-fiber textiles, these composites are tough to break down, complicating circularity goals. A Vogue Business report underscores the fragmented biomaterials industry, noting a projected 133-million-tonne shortfall in low-impact materials by 2030, as forecasted by Boston Consulting Group. This supply-demand gap, coupled with limited investment in scalable biomaterial ventures, creates a bottleneck for brands aiming to scale sustainable production.

Sourcing certified sustainable composites also carries a hefty price tag, particularly for smaller brands. The complexity of ensuring ethical supply chains tracing every fiber from origin to finished product adds another layer of challenge. Consumers, too, pose a hurdle. Some remain skeptical of synthetics, even recycled or bio-based ones, associating them with skin irritation or environmental harm. Clear, transparent labeling is essential to build trust, as is navigating tightening global regulations that demand accountability in sustainability claims.

Opportunities for Growth

Despite these challenges, mixed materials are unlocking new possibilities. They're enabling innovative product categories, like adaptive underwear for those with mobility challenges or hybrid athleisure-innerwear that blurs the line between activewear and intimates. Proprietary blends think hemp, recycled nylon, and a dash of spandex give brands a competitive edge, creating signature fabrics that stand out in a crowded market. Partnerships with manufacturers who upcycle textile waste can also drive cost savings while reinforcing eco-credentials.

The business case is strong. With the textile market poised to hit $3.75 trillion by 2032, brands investing in sustainable, high-performance fabrics are well-positioned to capture growth. Mixed materials aren't just a product feature they're a strategic asset, aligning with consumer values and market trends. By blending innovation with ethics, companies can carve out a niche in a sector where differentiation is everything.

A Future Woven with Purpose

The underwear we choose is personal, but its impact is global. Mixed-material fabrics are weaving a future where innerwear does more feels better, performs smarter, and treads lighter. Textile technologists envision a world of mono-recyclable hybrids, where fabrics can be reborn without waste. Digital tools, like AI-driven material mapping, are already optimizing blends for specific needs, from breathability to stretch. And consumers, more informed than ever, are demanding underwear that's not just sustainable but tailored to their lives.

This is a pivotal moment for the industry. Designers, manufacturers, and retailers must embrace mixed materials with transparency and innovation at their core. The fabrics of tomorrow's innerwear aren't just about what feels good they're about what does good. In a world where every choice counts, that's a revolution worth wearing.

Frequently Asked Questions

What are mixed-material fabrics in underwear and why are they becoming popular?

Mixed-material fabrics combine natural fibers like cotton, bamboo, or modal with synthetic materials like elastane, recycled nylon, or polyurethane to create hybrid textiles. These fabrics are gaining popularity because they offer superior performance, comfort, and sustainability compared to single-fiber materials. They deliver benefits like moisture-wicking, stretch, durability, and eco-friendliness while meeting consumer demand for planet-friendly underwear options.

What are the main challenges with recycling mixed-material underwear?

The biggest challenge with mixed-material fabrics is that they're extremely difficult to recycle because different fiber types can't be easily separated during the recycling process. Unlike single-fiber textiles, cotton-elastane or polyester-bamboo blends create complex composites that complicate circularity goals. Additionally, there's a projected 133-million-tonne shortfall in low-impact materials by 2030, making it harder for brands to source sustainable alternatives at scale.

How are hybrid fabrics changing the functionality of modern underwear?

Hybrid fabrics are transforming underwear from basic undergarments into high-performance products that serve multiple functions. Examples include period underwear that combines bamboo, cotton, and waterproof polyurethane for leak-proof protection, maternity shapewear that blends micromodal's softness with elastane's stretch for comfortable support, and adaptive underwear designed for people with mobility challenges. These innovations create underwear that performs smarter, feels better, and meets specific lifestyle needs.

Disclaimer: The above helpful resources content contains personal opinions and experiences. The information provided is for general knowledge and does not constitute professional advice.

You may also be interested in: Comfort-First vs Push-Up: How Preferences Are Changing

Uncomfortable underwear shouldn't steal your confidence. At Andcircus, we craft ultra-soft, sustainable Lenzing Modal Micro® innerwear for every body, XS to 5XL. From briefs to bras, our custom packs fit you perfectly. Shop risk-free with our 100% satisfaction guarantee and embrace comfort that includes everyone. #LoveEveryBody. Shop Now!