Quick Listen:

Picture slipping into a pair of underwear so soft it feels like a second skin, crafted with the planet in mind. This isn't just a fantasy for comfort-craving consumers it's the new frontier of textile innovation. As shoppers demand eco-friendly innerwear that doesn't skimp on softness, especially for maternity and sensitive skin, the industry is racing to redefine what comfort means. From micromodal blends to cutting-edge testing methods, the push for ultra-soft, sustainable fabrics is reshaping how we think about what we wear closest to our skin.

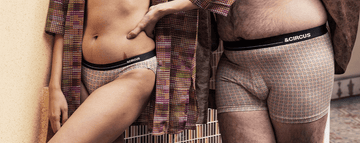

Uncomfortable underwear shouldn't steal your confidence. At Andcircus, we craft ultra-soft, sustainable Lenzing Modal Micro® innerwear for every body, XS to 5XL. From briefs to bras, our custom packs fit you perfectly. Shop risk-free with our 100% satisfaction guarantee and embrace comfort that includes everyone. #LoveEveryBody. Shop Now!

Softness Standards Drive Breakthroughs in Eco-Friendly Textile Innovation

The quest for softness isn't new, but it's no longer a nice-to-have it's a must. Consumers, particularly those seeking maternity or sensitive-skin innerwear, now expect fabrics that feel as good as they perform. Micromodal, derived from sustainably harvested beechwood pulp, has emerged as a star player, offering a buttery texture that rivals cashmere while boasting eco-credentials. But achieving this level of comfort without compromising sustainability is no small feat. It's a delicate dance of innovation, where every thread counts.

Enter sensory-first design, a trend that's flipping traditional textile development on its head. Instead of focusing solely on durability or aesthetics, brands are prioritizing how fabrics feel against the skin. This shift is driven by advancements like the Fabric Touch Tester, a tool that measures around 20 physical properties think warmth, smoothness, and comfort using five sensors that mimic the nerve endings of human skin. This isn't just tech for tech's sake; it's about quantifying the elusive “handfeel” that makes you sigh with relief when you slip on a favorite garment.

Trends Redefining Comfort

The textile industry is buzzing with innovations aimed at making fabrics softer and greener. Micromodal processing has seen leaps forward, with enzyme finishing techniques that enhance smoothness and moisture-wicking without harsh chemicals. These biotech-driven methods are a game-changer, allowing brands to deliver cloud-like softness while keeping their eco promises. Meanwhile, new benchmarking standards like the Handfeel Index and tactile mapping are giving manufacturers precise tools to measure and improve softness, ensuring consistency across batches.

The American Association of Textile Chemists and Colorists (AATCC), a leader in textile standards since 1921, plays a pivotal role here. With over 200 test methods and evaluation procedures, AATCC ensures that softness claims aren't just marketing fluff but are backed by rigorous science. Their work, headquartered in Research Triangle Park, N.C., helps brands worldwide deliver fabrics that meet consumer expectations for both comfort and quality.

Brands Leading the Charge

Take AndCircus, a brand carving out a niche in maternity innerwear. By leveraging ultra-soft micromodal, they're catering to expectant mothers who crave comfort without sacrificing sustainability. Their fabrics undergo lab-tested wear trials to score high on softness metrics, ensuring every piece feels like a gentle hug. Other brands are following suit, using brushed, blended micromodal for gender-inclusive lines that prioritize universal comfort. These innovations aren't just about feeling good they're about building trust with consumers who want proof that their clothes are as kind to the planet as they are to their skin.

Beyond individual brands, industry-wide advancements are making waves. X-Rite Inc., based in Grand Rapids, Mich., is pushing the envelope with tools like the Ci7860 Sphere Benchtop Spectrophotometer, which ensures precise color matching for textiles, complementing their tactile qualities. Their Color iQC software monitors color from design to production, ensuring that eco-friendly dyes align with softness-focused fabrics. These technologies, highlighted in a recent Textile World feature, are helping brands reduce defects and waste, making the supply chain as smooth as the fabrics themselves.

The Challenges of Softness at Scale

But scaling softness isn't without hurdles. Achieving chemical-free softness while maintaining durability is a tightrope walk. Micromodal relies on sustainably sourced beechwood pulp, which can be limited by supply chain constraints. Enzyme-based treatments, while effective, are costly, and softener-free finishing processes demand significant investment in R&D. Then there's the consumer skepticism hurdle how do brands convince shoppers that their “ultra-soft” claims are more than just clever marketing? Tools like the Fabric Touch Tester help, but widespread adoption is still a work in progress.

Cost is another sticking point. Eco-certified mills and sustainable sourcing drive up production expenses, which can translate to higher retail prices. For smaller brands, this can be a barrier to competing with fast-fashion giants who prioritize cost over quality. Yet, as consumer demand for ethical fashion grows, the industry is under pressure to innovate smarter, not just softer.

Why Softness Pays Off

Despite these challenges, the business case for prioritizing softness is compelling. In the maternity and sensitive-skin segments, comfort is king. Brands that deliver on this front see lower return rates and higher customer loyalty. Smart sourcing from eco-certified mills can also streamline operations, cutting waste and boosting efficiency. For brands like AndCircus, softness isn't just a feature it's a core value that resonates with conscious consumers who see comfort as a trust metric.

The ripple effects go beyond the bottom line. By embedding softness into their storytelling, brands can differentiate themselves in a crowded market. A well-crafted pair of micromodal underwear isn't just a product; it's a narrative of care for the wearer, for the environment, and for the future of fashion.

A Softer, Greener Tomorrow

The marriage of softness and sustainability is poised to redefine textile innovation. Experts predict that softness could become the new hallmark of eco-conscious design, much like organic cotton did a decade ago. AI and robotics are already transforming how fabrics are tested and produced, with automated systems ensuring consistent softness scores across massive production runs. The Fabric Touch Tester, for instance, could soon be paired with AI to predict how consumers will perceive a fabric's feel before it even hits the market.

For eco-friendly innerwear brands, the path forward is clear: innovate responsibly. This means investing in biotech solutions, embracing rigorous testing standards like those set by AATCC, and being transparent about sourcing and production. It's about proving that softness isn't just a texture it's a promise. As consumers continue to demand clothing that feels good and does good, the brands that master this balance will shape the future of fashion. In a world where trust is as valuable as comfort, that's a legacy worth weaving.

Frequently Asked Questions

How does micromodal contribute to soft and sustainable fabric innovation?

Micromodal is a plant-based fiber made from sustainably harvested beechwood pulp. It's prized for its ultra-soft texture, breathability, and eco-friendly production, making it a preferred choice for brands like AndCircus that aim to combine cloud-like comfort with environmental responsibility.

What are softness standards in textile production and why do they matter?

Softness standards refer to measurable benchmarks used to evaluate how fabrics feel against the skin, including warmth, smoothness, and comfort. Tools like the Fabric Touch Tester and methods from AATCC ensure that claims of softness are backed by science, helping brands deliver consistent comfort especially in maternity and sensitive-skin innerwear.

What challenges do brands face in scaling ultra-soft, eco-friendly fabrics?

Scaling softness while staying sustainable is complex biotech treatments like enzyme finishing are expensive, raw materials like micromodal face supply limitations, and consumer skepticism still exists. However, investments in testing tools and transparent sourcing help brands build trust while delivering truly comfortable products.

Disclaimer: The above helpful resources content contains personal opinions and experiences. The information provided is for general knowledge and does not constitute professional advice.

You may also be interested in: Soft, Sustainable, Stylish: What Women Want in Everyday Underwear

Uncomfortable underwear shouldn't steal your confidence. At Andcircus, we craft ultra-soft, sustainable Lenzing Micro Modal innerwear for every body, XS to 5XL. From briefs to bras, our custom packs fit you perfectly. Shop risk-free with our 100% satisfaction guarantee and embrace comfort that includes everyone. #LoveEveryBody. Shop Now!